Hot Product

- Hydrocyclone Group

Hydrocyclone group is widely used in coal preparation plant...

- Slurry Pump

Slurry pump is mainly used in mining, power plant, dredging, metallurgy...

- Polyurethane Dewatering Screen Panel

In addition to the performance of...

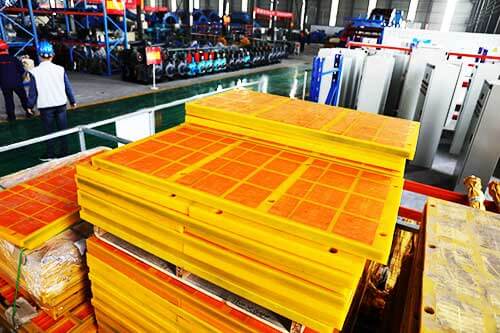

Polyurethane Screen Panels Suppliers

Date: 2021-08-05 From: Longding Author: admin

The polyurethane screen plate produced by LZZG is a convenient plate-type polyurethane screen panel with a simple structure, convenient installation, and reliable use, which is mainly used as the sieve plate of the dewatering screen for dehydration. The plate-type polyurethane screen fundamentally solves the problems of low opening rate, heavyweight, inconvenient installation, and replacement of the polyurethane screen, and significantly improves the processing, production capacity, dehydration efficiency of the vibrating screen, and prolongs the service life of the screen.

The convenient plate-type polyurethane screen includes the screen plate and mounting frame. The installation frame is composed of flat panel support, two parallel vertical panels arranged on the flat panel support along the length direction of the flat panel support, and a plurality of studs arranged along the length direction of the vertical panel and connected between the two vertical panels. The lower part of the sieve plate surface frame is provided with a semi-open circular hole corresponding to the pin, or a recess or protrusion corresponding to the protrusion or recess on the inner side of the vertical plate, and the distance between the inner sides of the two vertical plates is equal to twice the sieve plate The width of the board border.

Polyurethane is the first choice for making vibrating screens, because of the good wear resistance and screen penetration properties. The plate-type polyurethane screen has the advantages of small area, low mold opening cost, easy quality control, and more importantly, only a small screen needs to be replaced when the screen surface is damaged. It is well received by the manufacturers and users, and it greatly reduces the production cost and the use cost.

But the plate polyurethane screen still has the following problems

1. The structure of the rail seat increases the thickness of the screen plate, which leads to an increase in the weight of the screen plate, thereby increasing the dynamic load of the vibrating screen, and affecting the service life and production efficiency of the vibrating screen.

2. More molds are required, the production is complicated, and more materials are used. Increase production and production costs.

Previous:Hydrocyclone Separator Design Calculation

Next:Speed Regulation of Ore Sand Pump by Cyclone in Concentrator

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry