Hot Product

- Hydrocyclone Group

Hydrocyclone group is widely used in coal preparation plant...

- Slurry Pump

Slurry pump is mainly used in mining, power plant, dredging, metallurgy...

- Polyurethane Dewatering Screen Panel

In addition to the performance of...

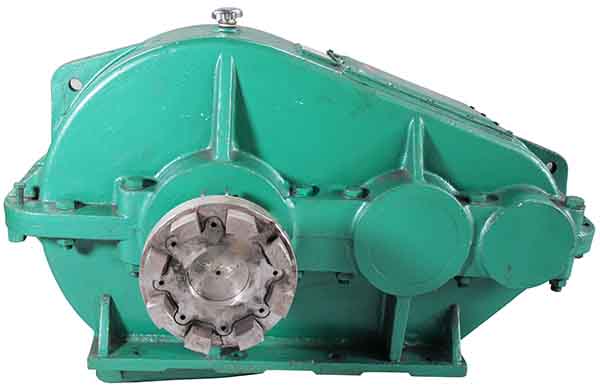

Working Principle of Gear Reducer

Date: 2022-03-24 From: Longding Author: admin

The gear reducer uses all levels of gear transmission to achieve the purpose of speed reduction. The reducer is composed of gear pairs at all levels, and the small gear can be used to drive the large gear to achieve a certain purpose of deceleration. By adopting a multi-stage structure, the speed can be greatly reduced.

The gear reducer is a power transmission mechanism that uses the speed converter of the gear to reduce the number of revolutions of the motor to the desired number of revolutions and obtain a large torque. Gear reducers are generally used for transmission equipment with low speed and high torque. The purpose of deceleration is achieved by meshing the gear with a small number of teeth on the input shaft of the reducer with the large gear on the output shaft with the power of the motor, internal combustion engine or other high-speed operation. Ordinary reducers will also have several pairs of gears with the same principle to achieve the ideal deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

Reduce speed while increasing output torque. The torque output ratio is multiplied by the motor output and the reduction ratio, but be careful not to exceed the rated torque of the reducer. Deceleration reduces the inertia of the load at the same time, and the reduction of inertia is the square of the reduction ratio.

Application of gear reducer

1. The high-speed shaft rotation is not more than 1500 rpm.

2. The peripheral speed of the gear drive is not more than 20 m/s.

3. The working environment temperature is -40-45℃. If it is lower than 0℃, the lubricating oil should be preheated to above 0℃ before starting.

4. The gear reducer can be used for both forward and reverse directions.

Gear reducer features

1. The gears are made of high-strength low-carbon alloy steel through carburizing and quenching, and the tooth surface hardness reaches HRC58-62.

2. High transmission rate. The single-level is greater than 96.5%, the double-level is greater than 93%, and the third level is greater than 90%.

3. Smooth operation and low noise.

4. Small size, lightweight, long service life, and high bearing capacity.

5. Easy to disassemble and inspect, easy to install.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry